The world of manufacturing has undergone a major transformation over the past few decades. Gone are the days of slow, manual assembly lines. In today’s world, automation is leading the way, and it’s reshaping how products are made. But what does that really mean for manufacturers, and why does it matter to the everyday consumer? Let’s dive into how automation is changing the game, one factory at a time.

What Exactly is Manufacturing Automation?

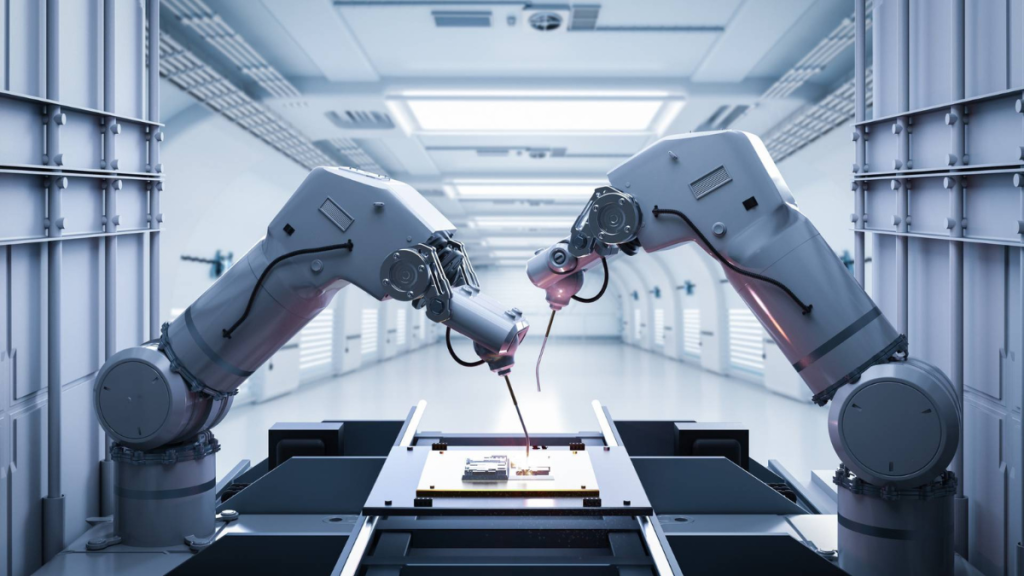

At its core, manufacturing automation is the use of technology, whether robots, AI, or machines, to take over tasks that were once done by human workers. Automation helps speed up production, reduce errors, and improve overall quality. Imagine a machine that can assemble a product faster and more accurately than any human, well, that’s automation in action.

There are a few types of automation that play a big role in manufacturing:

- Fixed Automation: This is the kind where machines are set up to perform a specific task repeatedly, like an assembly line where the same thing happens over and over.

- Programmable Automation: Here, machines can be reprogrammed to perform different tasks as needed, which is super useful for companies that need flexibility in their production process.

- Flexible Automation: This combines the best of both worlds, allowing machines to adapt to different tasks quickly, without major downtime.

You might be wondering, why does this matter? It’s all about making manufacturing faster, more efficient, and cost-effective. But let’s explore exactly how automation is making that happen.

Why is Automation a Big Deal?

Here’s where it gets interesting. Automation isn’t just a fancy buzzword, it’s revolutionizing the manufacturing industry in some pretty major ways. Let’s break down some of the key benefits:

- Increased Efficiency: Machines don’t need breaks, and they don’t get tired. This means they can work around the clock, which speeds up production and reduces downtime.

- Cost Savings: Let’s face it, labor can be expensive. By automating certain tasks, manufacturers can cut down on labor costs while still maintaining production levels. It’s a win-win.

- Enhanced Safety: Some jobs in manufacturing can be dangerous, especially when heavy machinery or hazardous materials are involved. Automation can take on the riskier tasks, keeping workers safer.

- Consistency and Quality Control: Machines are precise. They don’t make mistakes the way humans can. With automation, manufacturers can ensure that each product is made to the same high standard, every single time.

- Scalability: As demand for products increases, it can be tough to keep up. But with automation, manufacturers can quickly ramp up production to meet growing needs without sacrificing quality.

Which Industries Are Using Automation?

You’d be surprised just how many industries rely on automation today. It’s not just about robots in car factories, automation is making waves in many different sectors:

- Automotive: From robotic arms assembling car parts to automated quality checks, the automotive industry has embraced automation to speed up production and reduce human error.

- Electronics: When it comes to tiny, intricate components, humans can’t match the precision of machines. Automation ensures these parts are made quickly and with high accuracy.

- Aerospace: In the aerospace industry, precision is everything. Automated systems help produce complex parts and components that must meet exacting standards.

- Sheet Metal Fabrication: Even in processes like the sheet metal fabrication process, automation plays a crucial role. Machines are now capable of cutting, bending, and shaping metal with incredible accuracy, reducing production time and waste.

The Technologies Powering Automation

So, how is all of this happening? The answer lies in technology. Several key innovations are making automation possible in today’s manufacturing world:

- Robots and Cobots: Robots are a staple in modern factories, performing repetitive tasks that humans once did. But it’s not just about replacing people, cobots (collaborative robots) are designed to work alongside humans, improving productivity without replacing jobs.

- AI and Machine Learning: Artificial intelligence is becoming a game-changer in manufacturing. With AI, machines can analyze data, predict when maintenance is needed, and optimize production schedules.

- IoT (Internet of Things): The IoT is connecting machines, sensors, and devices in factories, enabling real-time data sharing and improving efficiency across the entire production process.

- 3D Printing: Known as additive manufacturing, 3D printing allows manufacturers to create custom parts and prototypes without the waste typically associated with traditional production methods.

The Challenges to Overcome

No system is without its hurdles. Here are a few challenges manufacturers face when adopting automation:

- Initial Investment: Automation technology can be expensive to install. While it pays off in the long run, some smaller businesses may struggle with the upfront costs.

- Resistance to Change: Some employees might be skeptical about automation, worrying about job security or simply being resistant to change. It’s important for companies to offer training and help workers transition smoothly into the new system.

- Skill Gaps: With new technology comes the need for new skills. Automation requires workers who can manage and maintain these advanced systems, and there’s a growing demand for tech-savvy professionals in manufacturing.

What’s Next for Automation?

Looking ahead, the role of automation in manufacturing is only going to grow. We’re talking about fully automated factories, where machines handle everything from production to quality checks, with minimal human intervention. As technology advances, here’s what we can expect:

- Smarter AI: As AI continues to evolve, it will make manufacturing processes even more efficient by optimizing production schedules, improving quality control, and even designing products.

- Sustainability: Automation isn’t just about efficiency, it’s also about sustainability. Automated systems can help manufacturers reduce waste, use energy more efficiently, and adopt eco-friendly practices that benefit both the bottom line and the planet.

- Autonomous Factories: Imagine a factory where robots do everything, from assembly to inspection, all while communicating seamlessly with each other. The future of manufacturing is moving toward fully autonomous systems that require little to no human involvement.

Wrapping It Up

At the end of the day, automation is changing the face of manufacturing as we know it. From increasing efficiency and safety to reducing costs and waste, the benefits are clear. While there are challenges, the future of manufacturing is bright, with automation playing a huge role in shaping what’s next. Whether it’s the automotive industry, electronics, or even the sheet metal fabrication process, automation is pushing industries toward faster, smarter, and more sustainable production.

What do you think? Will automation continue to revolutionize manufacturing, or are there still some things that only humans can do? Only time will tell.