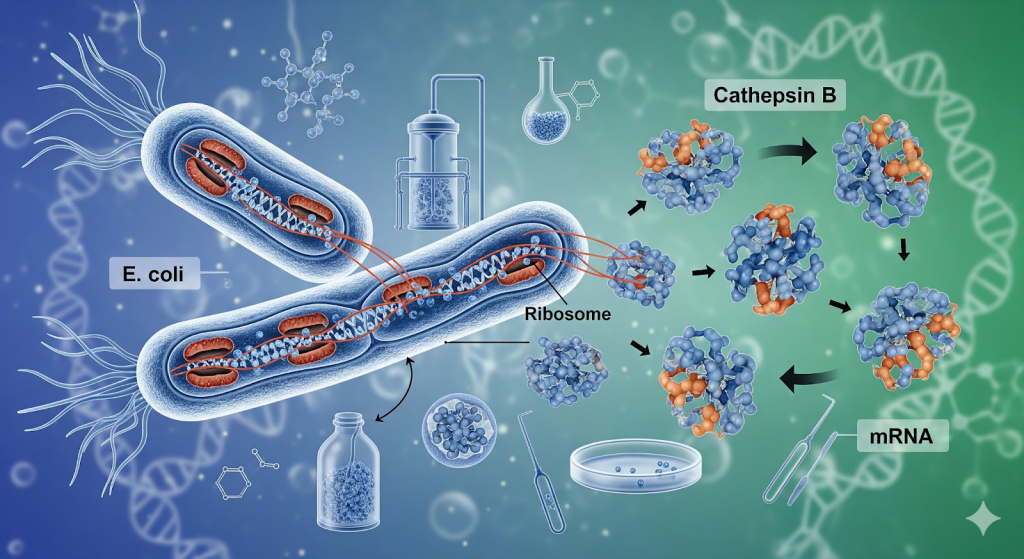

E. coli has become one of the go-to choices for researchers when it comes to mass-producing important enzymes like recombinant rat Cathepsin B (Ctsb) for studying diseases like cancer.

However, since Ctsb is a complex animal protein, it doesn’t always fold correctly inside the simple bacterial factory. Therefore, to get a working product, researchers need to fine-tune or optimize every step of the production process.

This blog post will explore the critical factors influencing the expression of recombinant Ctsb in E. coli, including host strain selection, vector design, induction conditions, solubility strategies, and purification techniques.

Choosing the Right E. coli Strain

Not all E. coli strains are the same. Not to mention that your choice of strain can significantly influence the solubility and activity of Ctsb. The following are the three commonly used strains:

- BL21(DE3): It is the most commonly used strain because it carries the T7 RNA polymerase under control of the lacUV5 promoter, making it ideal for T7-based expression vectors.

- Rosetta strains: Rare tRNAs that help translate eukaryotic genes more efficiently in E. coli. Since Ctsb originates from mammals, codon bias can be a problem, and Rosetta strains often improve yields.

- Origami strains: These enhance disulfide bond formation in the cytoplasm by mutating thioredoxin and glutathione reductase systems. Because Cathepsin B contains multiple disulfide bonds, this can improve folding and activity.

Vector Design and Promoter Strength

Plasmid vector: These carry essential instructions for making a protein in a cell; therefore, the plasmid needs to be carefully designed to ensure that it works properly inside the cell.

Fusion tags: Adding solubility-enhancing fusion partners like GST (Glutathione S-transferase) or MBP (Maltose-binding protein) often improves folding and solubility. These tags can later be cleaved off after purification.

Signal peptides: Targeting recombinant Ctsb to the periplasm (using signal sequences such as pelB) can promote correct disulfide bond formation and yield more active enzyme.

NOTE: Promoter strength is a major design consideration, as these sequences determine the rate at which the factory manufactures the protein.

Induction Conditions

- Inducer Concentration (The Start Signal): Using a weak start signal (low IPTG) slows down production. Slower production is often better, as it gives the protein time to fold correctly instead of rushing and becoming messed up.

- Growth Phase (When to Start): Start production when the bacteria are healthy and growing well, but not so crowded that they can’t handle the extra work.

- Temperature: Dropping the temperature (e.g., to 16°C) after starting the production process is like slowing down the conveyor belt. This slows down synthesis and gives the protein extra time to fold into its correct, active shape.

Solubility Strategies

If proteins are made too fast or incorrectly, it can lead to misfolded proteins, which are not soluble. Therefore, it is important to ensure that the protein is soluble. Here’s some strategies to improve solubility:

- Use co-expression of molecular chaperones (helper proteins) such as GroEL/GroES or DnaK/DnaJ/GrpE to assist folding.

- Use fusion tags (MBP, GST, or NusA) to ensure protein stays smooth and dissolved.

NOTE: If inclusion bodies are unavoidable, refolding protocols using stepwise removal of denaturants (urea or guanidine hydrochloride) combined with redox-shuffling agents (reduced/oxidized glutathione) can help restore active enzyme.

Purification Strategies

Once the culture’s spun down and lysed, you’re looking at a crowded mix. The job now is to get Ctsb out cleanly and keep it happy.

- Start gentle.

- Keep everything cold.

- If you’ll assay activity later, skip broad cysteine-protease inhibitors during lysis (they do what they’re supposed to—block your enzyme).

- A quick 20–30 min spin gives you a clear supernatant to start from.

Confirming Activity

It should be noted that purification is not the final step; achieving activity is. Start with a quick plate read using a fluorogenic dipeptide substrate (e.g., Z-Arg-Arg-AMC). When Ctsb cleaves, the signal rises; most readers run AMC at ~360–380 nm excitation, ~440–460 nm emission. Build a small standard curve with free AMC so your numbers mean something.